Mist Eliminators

What are Mist Eliminators?

Knitted Mesh Mist Eliminators are porous blankets of knitted, layered or rolled stainless steel mesh. These Mist Eliminators are designed for effective removal of entrained liquid from vapor. Knitted Mesh Mist Eliminators can be fabricated in any size and shape which then can be installed in new or existing vessels.

Knitted Mesh Mist Eliminators are porous blankets of knitted, layered or rolled stainless steel mesh. These Mist Eliminators are designed for effective removal of entrained liquid from vapor. Knitted Mesh Mist Eliminators can be fabricated in any size and shape which then can be installed in new or existing vessels.

Advantages and Benefits:

- Improve process efficiency

- Increase throughput capacity

- Reduces air pollution problems

- Eliminate loss of product

- Improve product quality

- Reduce product contamination

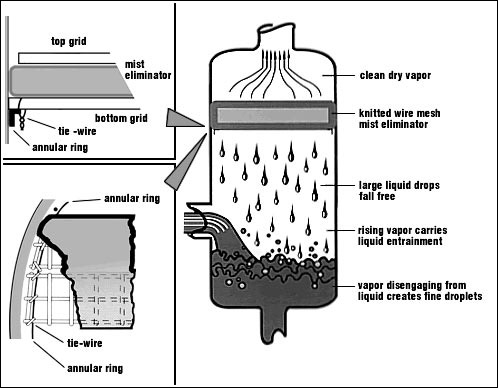

How They Operate:

Vapor and entrained liquid passes through the Knitted Mesh Mist Eliminators. The vapor moves easily but the liquid, because of the density of the mesh, contacts the wire surfaces and holds. As volume enters the pad and collects, droplets grow in size, and as a result follow the wire down to the bottom of the mesh and fall. The vapor proceeds upward.

Applications of the Knitted Mesh:

Scrubbers, Separators Vessels and Knock Out Drums

Knitted Mesh removes oil and water from compressed air.

Knitted Mesh removes hydrocarbon liquids from natural gas.

Evaporators

Knitted Mesh products condensate suitable for boiler feed water.

Absorbers

Knitted Mesh removes almost all liquid entrainment of process liquids, hence clean dry gas with increased efficiencies.

Refineries

Knitted Mesh is used in vacuum towers.

Knitted Mesh is used in lube towers.

Sulphur Plant Coalescers

Knitted Mesh removes sulphur mist from acid gas steam in sulphur condensers and gas scrubbers.

Steam Drum

Knitted Mesh prevents water carry over to turbines.

Knitted Mesh provides clean dry steam.

Design Information:

Knitted Mesh Construction:

Construction of Knitted Mesh units are not limited by size or shape. For larger equipment, where one piece is not practical, sectional mesh pads are used. Mesh pads of 4" or 6" thickness are the most common. Thickness can far exceed 6" if required.

In smaller equipment, one-piece mesh pads will provide the most convenient method of installation. Diameters are usually limited to a maximum of 42". Thickness is normally 4" to 6".

Data Required:

|

|

Special Conditions:

Where entrainment less than 5 microns must be removed, two units can be installed in series. The first collects the mist into large droplets, which are easily removed by the second unit. Where coking is a potential problem, variable density mist eliminators can be used. Larger openings in the lower section resist clogging, finer openings in the upper section provide exellent seperation.Materials:

Stainless Steel

304L, 316L, and others

Special Aloys

Inconel, Monel, and others